Sandblasting can be used for mega structures like oil rigs and it can be used for creating design for small ornamental items, and also for precision work on moulds for dentures. The sandblasting effects comes with different equipment and different sandblasting media. Its usage is far and wide. Present us with the material and we will help you to find an equipment and media most suitable for you.

Our current setup covers a total 2600m2of space. First phase setup consists of an auto chamber blasting machine with chamber Height 3m x Width 2.2m and a rolling sand machine.

Our auto chamber blasting machine capable to blast most of the steel item for shipbuilding and construction on the market. Each lot will only consume 10-15 minutes to complete.

The rolling sand machine is use for smaller item such as pipe fittings and small size steel products.

The 2 blasting machines able to reduce man power requirement especially during this pandemic. We able to reduce rely on manpower, operate with less interrupt by the current pandemic.

After blasting, the goods will transfer to coating zone to coat according to client specification. 15 painting stations will be setup and 5 painting compressor is ready for service.

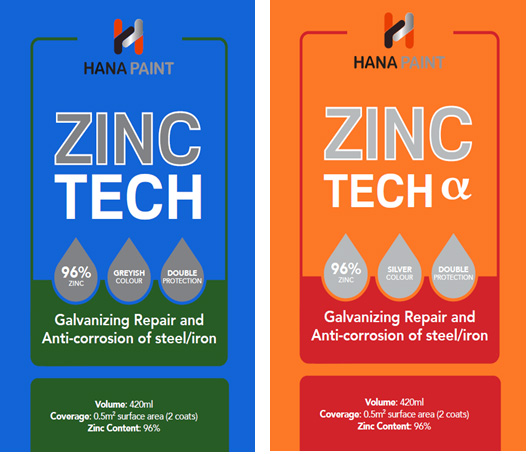

Cold Galvanising is available as an additional service through our partnership with HANA Paint using Zinc Tech and Zinc Techα.

Zinc Tech and Zinc Tech α are Zinc rich dry film galvanising system.

It consists of ultra-fine Zinc particles made to protect metals from corrosion far longer than any other technology.

Contact us to find out more about this amazing technology!

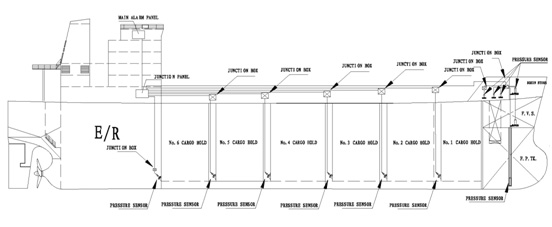

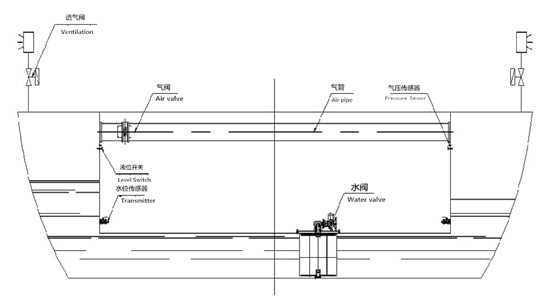

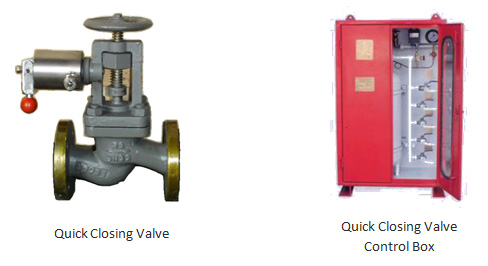

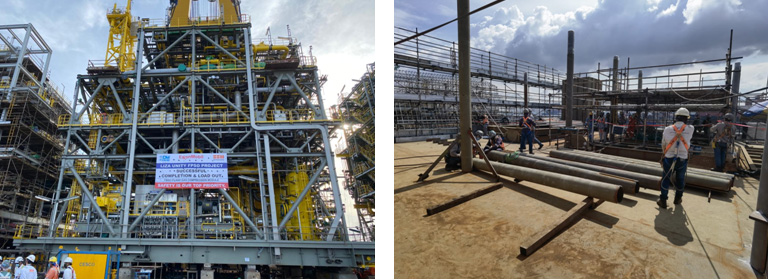

Eco Engrg explores labour supply in the fabrication service sector for the marine and offshore industry. Our labour is skilled in all materials for pipe spool fabrication, namely Carbon Steel, Stainless Steel, Copper Nickel and Super Duplex. They are also trained to do installation and line pipe testing.

Eco Engrg also provides solutions for Carbon Steel structure fabrication and erection. Fabrication services includes:

1.Super Structure

2.Pancake

3.Pipe Support

4.Outfitting

Steel Framing

Structure Assembly