Eco Engrg also provide 4 types of full systems solutions.

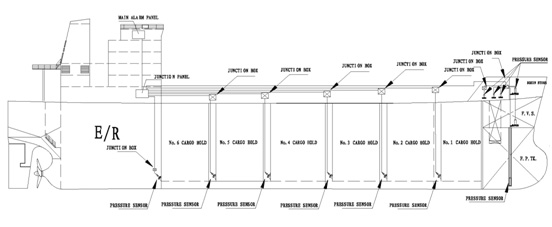

Valve Remote Control System

The Valve Remote Control System is used for many piping systems on marine vessels.

We supply 4 types of packages:

1.Hydraulic Actuation System

2.Pneumatic Actuation System

3.Electric Actuation System

4.Electro-hydraulic Actuation System

Anti-heeling System

Heeling refers to the tilting of the ship. It is primarily caused by uneven cargo load, sharp turns and high-intensity winds or waves. The Anti-heeling System is designed to check the inclination of the ship and, if allowed, automatically compensate the forces which cause it. Especially with container ships and ferries, the Anti-heeling System can prevent critical ship orientations.

The Anti-heeling System can work in conjunction with the Stability Control System and the Valve Remote Control System for Bilge and Ballast valve control. The integrated system can be monitored and parameterized from a TFT touch panel.

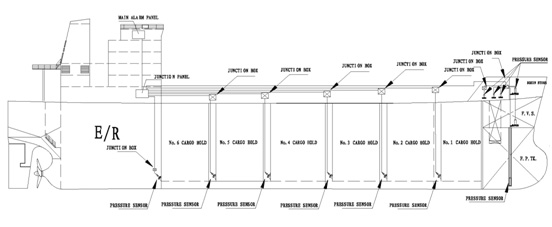

Water Ingress System

DMH provides solutions with proper compliance with the rules and regulations - Mandatory SOLAS XII/12 requiring installation of the Water Ingress Alarm System on bulk carriers. The Water Ingress Alarm System is designed to detect the presence of water or bilge in cargo holds or empty spaces.

It consists of water-level sensors and alarming indication equipment. The sensors come in direct contact with the water. Once the water reaches pre-alarm and main alarm level, the control panel sends out corresponding visual and audible alarm signals to indicate the position of the cabin where there is water ingress. The system continually monitors the entire set of equipment and triggers audible & visual alarms when detecting failures in the system.

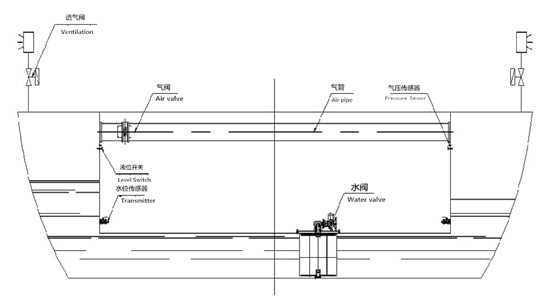

Active Roll Damping System

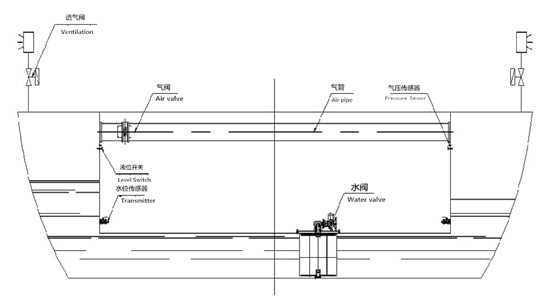

The Active Roll Damping System is a roll damping system equipped with a monitoring and control system on the basis of a passive U-tube type anti-roll tank to assist ship crews in operating the ship stabilizer safely with maximum efficiency.

By constantly measuring the dynamic tank liquid level and the roll period of the ship, the system automatically adjusts the tank water oscillating period by restricting the air flow and/or water flow in between the interconnected tanks to achieve the required phase lag of approximately 90 degrees. It also optimizes the anti-rolling performance.

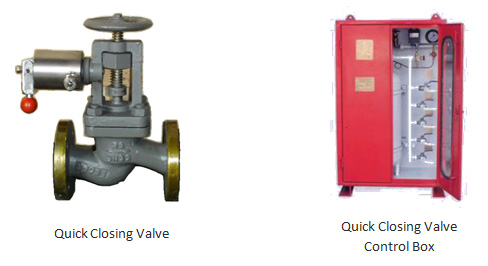

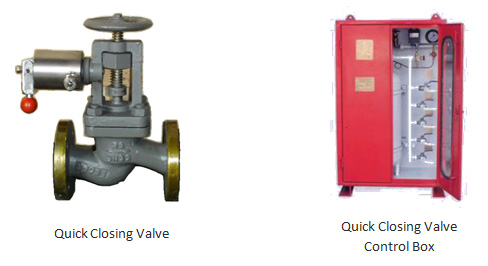

Quick Closing Valve System

The Quick Closing Valve System includes rope movement quick closing valve, air-actuated quick closing valve and hydraulic quick closing valve. They are used for marine Fresh Water, Fuel Oil and Lube Oil. The valve can be closed and opened normally. In case of emergency, emergency actions can be made by both manual and remote control method to close the valve immediately.

The Quick Closing Valve Control Box is a remote control plant suitable for fuel oil tank, lube oil tank and daily supplying fuel oil tank of ships. Its purpose is to shut off oil circuits and prevent any fire from spreading.

Gas Detection System

The Gas Detection System is used to monitor the concentration of combustible gases in ambient air - the explosion limit ranges from 0% to 100%. The system consists of gas detectors and an alarm cabinet. The sensor technology is known as the catalyst combustion type. The technology can be used for specific gas detection and monitoring. This system is crucial as it is an effective way to prevent poisoning, explosion and fire, thus, ensuring the safety of lives and properties.

The gas detector is part of the State Quality Supervision and Inspection Centre (CQST) test, explosion-proof performance. In accordance with the GB3836.1-2000 and GB3836.4-2000 standard, explosion-proof mark for Ex ibⅡB T4 and ExdⅡCT6, the product must be composed of safe explosion-proof barrier for it to be used in places containing explosive gases - below the rank of ⅡA.